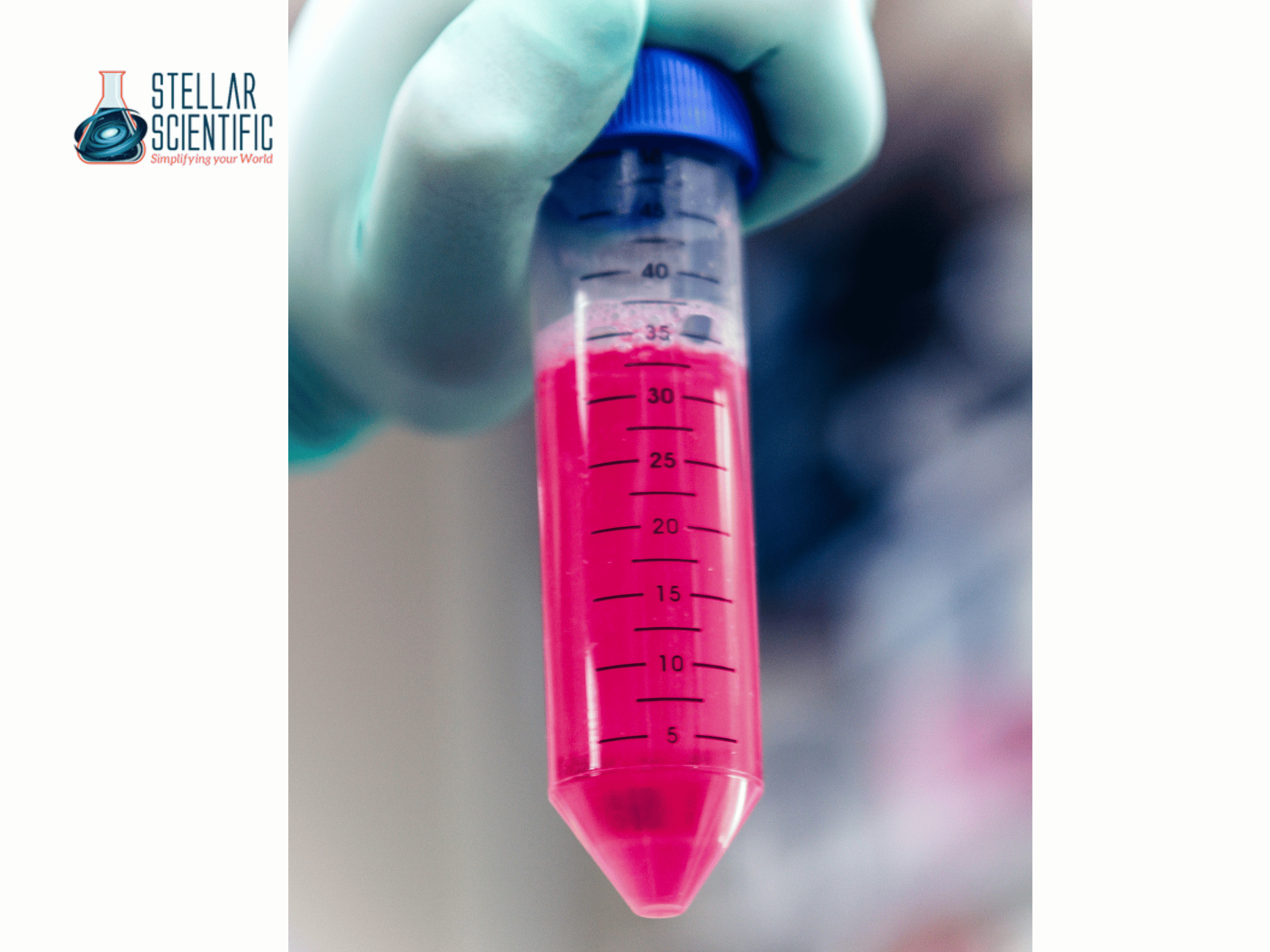

In laboratory settings, 5mL conical tubes are essential tools for handling small sample volumes. Understanding how these tubes respond to extreme conditions, such as freezing and autoclaving, is crucial for maintaining sample integrity and ensuring accurate results. This article explores the effects of these processes on 5mL conical tubes and offers best practices for their use.

Understanding 5mL Conical Tubes

5mL conical tubes are small, cone-shaped containers commonly used in laboratories for storing and centrifuging samples. They are typically made from polypropylene, a durable plastic known for its chemical resistance and ability to withstand various temperatures.

The Impact of Freezing on 5mL Conical Tubes

Freezing samples is a common practice to preserve biological materials. Polypropylene tubes can generally endure freezing temperatures down to -80°C. However, it's important to note that at temperatures below zero, the strength of polypropylene decreases, making the tubes more susceptible to damage if mishandled. Therefore, it's crucial to handle frozen tubes with care to prevent cracking or breaking.

Best Practices for Freezing:

-

Even Freezing: Ensure that samples freeze uniformly to prevent stress points that could lead to cracks.

-

Avoid Overfilling: Leave adequate space in the tube to accommodate sample expansion during freezing.

-

Proper Handling: Minimize mechanical stress on frozen tubes to reduce the risk of damage.

The Impact of Autoclaving on 5mM Conical Tubes

Autoclaving is a sterilization method that uses high-pressure saturated steam at 121°C. Polypropylene tubes can withstand autoclaving without significant loss of mechanical properties. However, caution is needed with the caps. Screw caps made from high-density polyethylene (HDPE) may warp under autoclave conditions, leading to potential leaks. It's advisable to use caps made from polypropylene and to slightly loosen them during autoclaving to prevent deformation due to pressure changes.

Best Practices for Autoclaving:

-

Cap Selection: Use polypropylene caps and loosen them slightly during autoclaving.

-

Avoid Overfilling: Prevent overfilling tubes to allow for pressure changes during the autoclaving process.

-

Inspect Post-Autoclaving: Check tubes and caps for any signs of deformation or damage after autoclaving.

Balancing Freezing and Autoclaving

When a laboratory protocol requires both freezing and autoclaving, it's essential to assess the cumulative impact on the 5mL conical tubes. Repeated exposure to extreme temperatures can degrade the material over time. Regular inspection of tubes for signs of wear, such as cracks or discoloration, is recommended to ensure ongoing reliability.

Understanding how 5mL conical tubes respond to freezing and autoclaving conditions is vital for their effective use in the laboratory. By following best practices, researchers can maintain sample integrity and ensure accurate experimental outcomes. For high-quality laboratory supplies, consider exploring the range of products offered by Stellar Scientific.