In the USA and around the world, laboratories are dealing

with a serious shortage of pipette tips with a special filter, or barrier, to

prevent aerosol contamination.

In large part, this sudden shortage of filter tip pipette tips is due to the explosion in molecular biology testing for SARS-CoV-2, as in RT-PCR testing and saliva testing for Coronavirus.

Prior to the COVID-19 pandemic, most pipette tips sold did not contain a filter since pipette tips are customarily used for routine liquid handling activities to transfer solutions and media from one location to another.

Using a pipette to transfer liquids works in a similar manner to using a straw to suck up liquid, placing a finger over one end of the straw to create a vacuum, then releasing the vacuum and depositing the liquid in a new vessel.

When liquids are transferred this way, the movement creates aerosols which can float out of the pipette tip into the shaft of the pipettor and re-emerge the next time the vacuum is released

The function of the filter or barrier tip is to protect sample integrity from cross contamination by blocking these aerosols so they remain in the tip which is discarded before the next sample is processed.

When conducting diagnostic molecular biology assays, the accuracy of the results depends on the quality of the sample.

A filter tip pipette tip becomes an absolute necessity to ensure no contamination occurs.

The CDC requires diagnostic laboratories to ensure their SARS-CoV-2 testing is done with a filter tip pipette tip for accurate results.

The increase in diagnostic molecular biology activities for COVID-19 testing “flipped the script” and suddenly the world needed more filter tip pipette tips than had ever been produced.

While there are many pipette tip manufacturing companies, there are limited sources for the material that goes into producing the barrier for the filter tip.

A major bottleneck ensued.

But this is just one bottleneck. There is another which could set the stage for a prolonged shortage of barrier tips well into 2021.

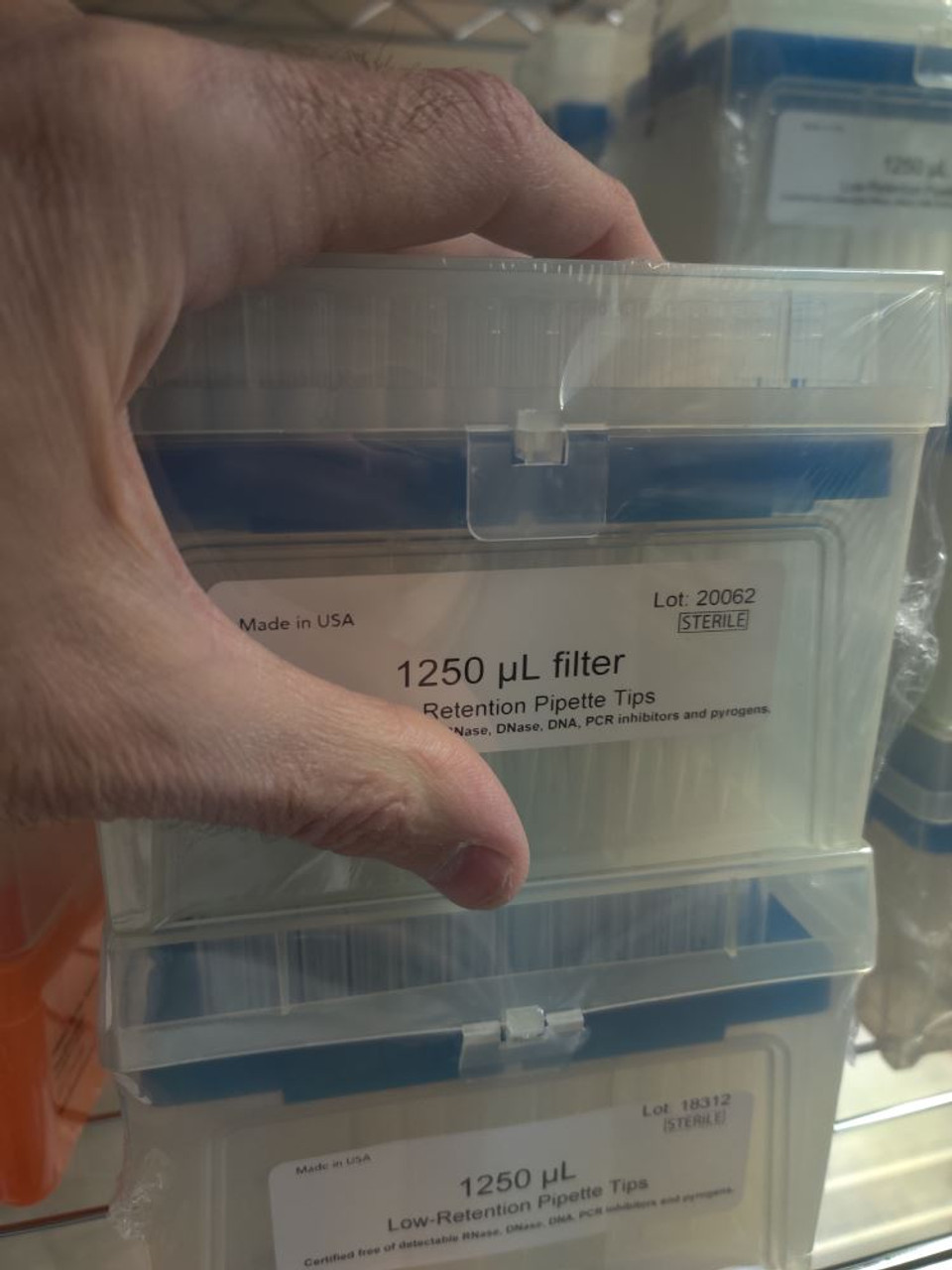

Filter tip pipette tips used for RT-PCR and other analytical molecular biology assays have two other key attributes; they must be certified free of any PCR inhibitors and they are sterilized.

To be certified “PCR clean” a filter tip pipette tip is made in a certified clean room in a process where no human contact can occur.

Typically pipette tips for PCR use are identified as being “RNase/DNase and human pyrogen free” – which is a fancy way of saying the plastic contains nothing which could contaminate or inhibit the genomic material that is transferred using the filter tip pipette tip.

There is no shortage of PCR clean plastic for making filter tip pipette tips, but trouble is brewing meeting the other requirement: Sterility.

There are only so many sterilizing facilities.

In addition to sterilizing filter tip pipette tips, these sterilizers must process other vital components needed for COVID-19 testing.

Things like transport tubes for VTM and transport media; 5mL screw cap tubes for collecting saliva samples, deep well plates for processing samples prior to running the RT-PCR assay, and more.

Sterilizers are drowning in demand.

What had been a two-week round trip is now stretching out into months.

Even if the shortage of filter material could be solved, how do we get around the problem of sterilizer logjam?

Perhaps the answer is: “Relax the sterility requirement”.

Doing so will not suddenly flood the market with an unlimited supply of filter tip pipette tips, but it would reduce pressure on manufacturers and bring more barrier tips sooner.

Some labs have already indicated approval with this suggestion.

What do you think?

Let us know at info@stellarscientific.com